Actuator Renovation, Upgrades & Installation: Engineering Reliability for Demanding Conditions.

NordenFlow provides professional renovation and upgrade services for electric, pneumatic, and hydraulic actuators. This technical approach extends equipment life and ensures peak performance in demanding environments. Every project is executed according to strict SIL loop validation and ATEX/IEC standards, providing a cost-effective alternative to full replacement without compromising on safety.

⚙️ Service Overview:

We support clients throughout the entire actuator lifecycle — from inspection and evaluation to complete field refurbishment and installation.

Our experts diagnose performance issues, replace worn components, and integrate the latest smart features to extend operational life and improve efficiency.

Core Capabilities:

- Actuator refurbishment and re-certification (pneumatic/electric/hydraulic)

- Replacement of seals, gears, motors, and control boards

- Field installation and alignment of existing valve assemblies

- Calibration and function testing after installation

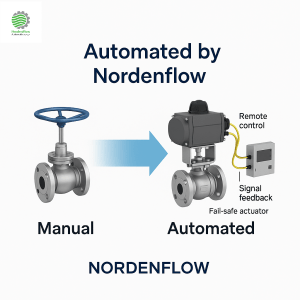

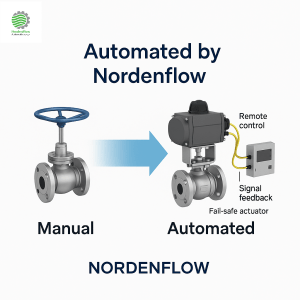

- Conversion of manual valves to automated systems

- Integration with solenoid valves, positioners, and PST modules

Modernization & Upgrades

Extend the life of your existing actuators with smart technology enhancements.

NordenFlow upgrades legacy units with advanced positioners, diagnostic modules, and communication interfaces to meet today’s automation standards.

Upgrade Options:

- Diagnostic Positioners (like IMI SHP-SIS) with feedback (4–20 mA / HART / Modbus)

- Local/remote control conversion

- Retrofit kits for obsolete actuator models

- Replacement of analog controls with digital systems

- Integration with control cabinets and SCADA networks

🧩 Benefit: Enhanced reliability, reduced downtime, and compatibility with modern control platforms.

Field Installation & Commissioning

Our field engineers perform on-site installation and commissioning of all actuator types — ensuring proper mechanical alignment, torque calibration, and control integration.

Installation Process Includes:

- Mounting & mechanical alignment

- Pneumatic or electrical connection

- Function & torque verification

- Signal and feedback calibration

- Full operational testing (open/close & fail-safe)

Standards:

- IEC 60079 / ATEX for Ex areas

- SIL loop validation (IEC 61508 / 61511)

- ISO 9001 service procedure

Documentation & Testing

A complete service report accompanies every actuator upgrade and installation, detailing calibration results, torque verification data, and compliance certificates.

Factory Acceptance Testing (FAT) and on-site validation are available upon request.