Comprehensive Engineering Services for Reliable Valve Automation Performance

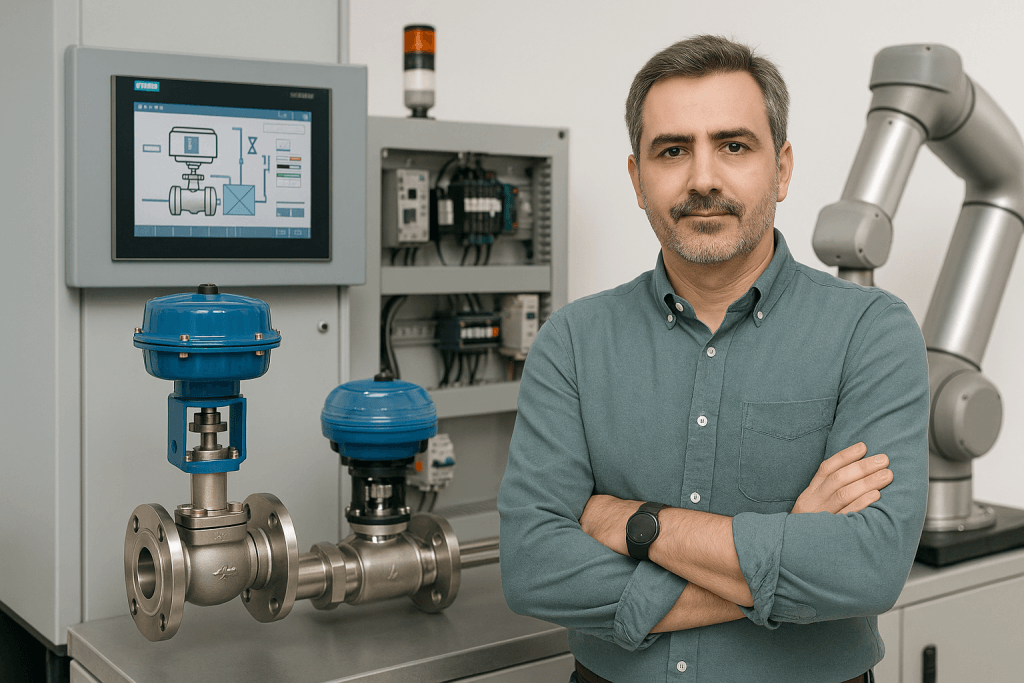

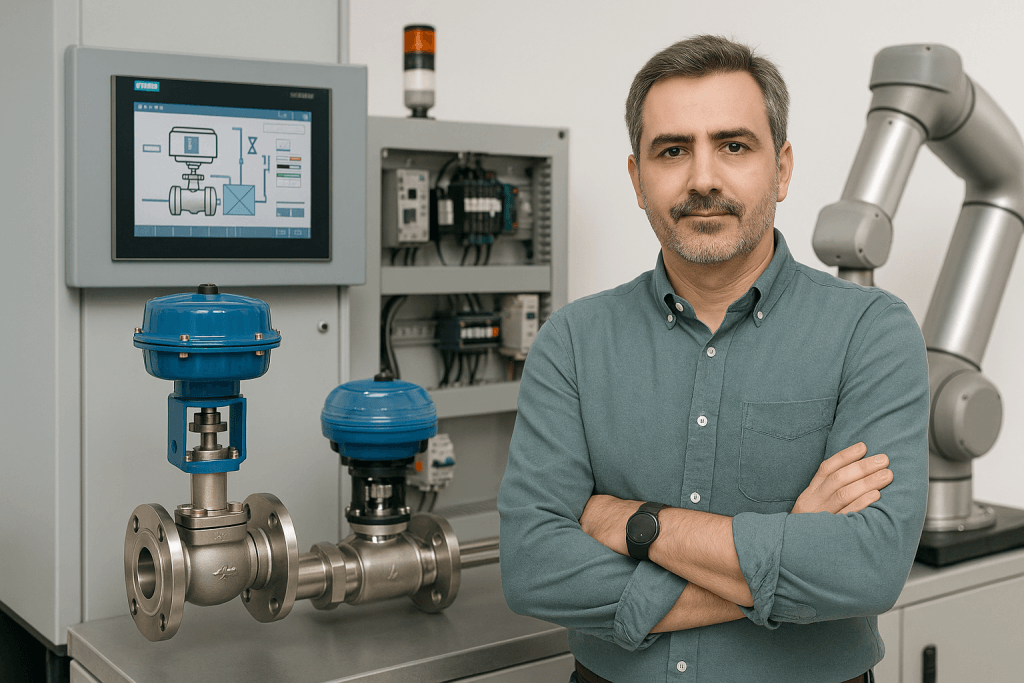

NordenFlow provides expert engineering and technical services focused on enhancing the performance, reliability, and safety of valve automation systems. Our expertise covers the full lifecycle of automated valves—from actuator refurbishment to complete system integration—ensuring long service life, reduced downtime, and strict compliance with SIL and ATEX requirements.

These systems are built for demanding industrial environments where reliability and functional safety cannot fail.

Our approach protects your assets and reduces the total cost of ownership by maximizing actuator service life.

These programs help asset owners maintain operational stability, reduce unplanned shutdowns, and comply with safety-integrity targets

Process Data: Media type, operating pressure (P1 & P2), and temperature range.

Safety Requirements: Desired SIL rating, fail-safe position (NC/NO), and ATEX zone classification.

Control Logic: P&ID requirements, preferred communication protocols (HART, Profibus, IO-Link), and PST integration.

We offer tailored training programs designed to enhance the competence of your engineers and technicians in complex valve automation systems. Our courses are focused on maximizing safety, optimizing performance, and ensuring regulatory compliance in the field. Key modules include;

- Actuator Sizing & Selection for critical applications, focusing on torque, speed, and environmental demands.

- Instrumentation & Control Component for Pneumatic, hydraulic, and gas-over-oil actuators