Engineered Flow Control & Process Automation Valves

NordenFlow provides engineered flow control solutions designed for the most demanding process loops. From high-pressure steam regulation to abrasive slurry handling, our automation valves are selected for their Cv/Kv precision, rangeability, and dynamic response.

We integrate IMI Norgren’s world-class pilot technology with heavy-duty valve bodies to ensure stable process control in Finnish pulp mills and energy plants.

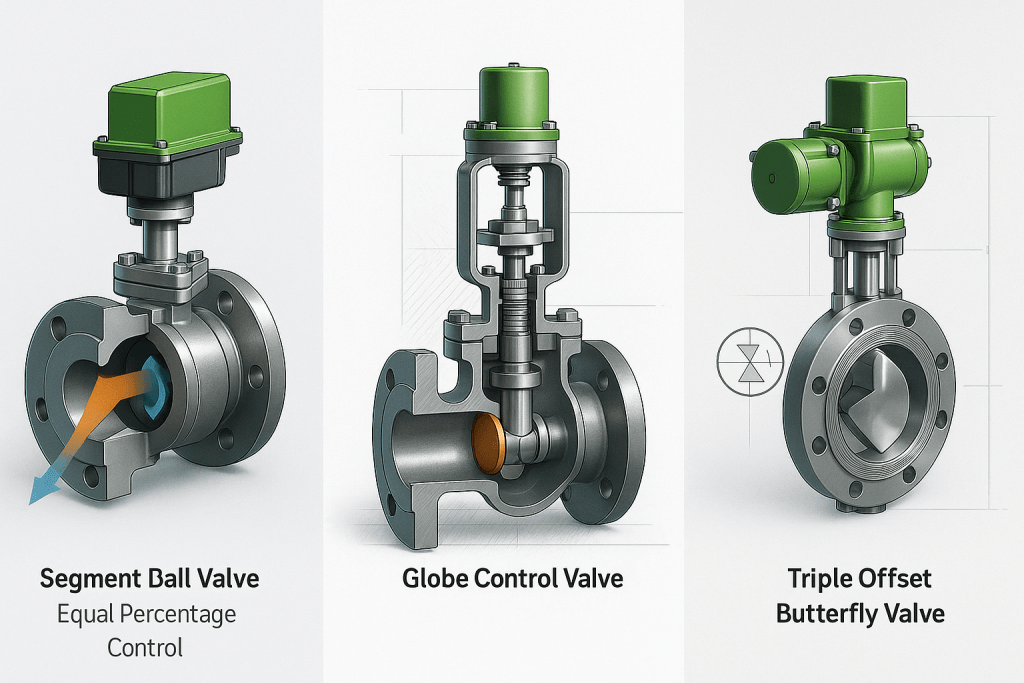

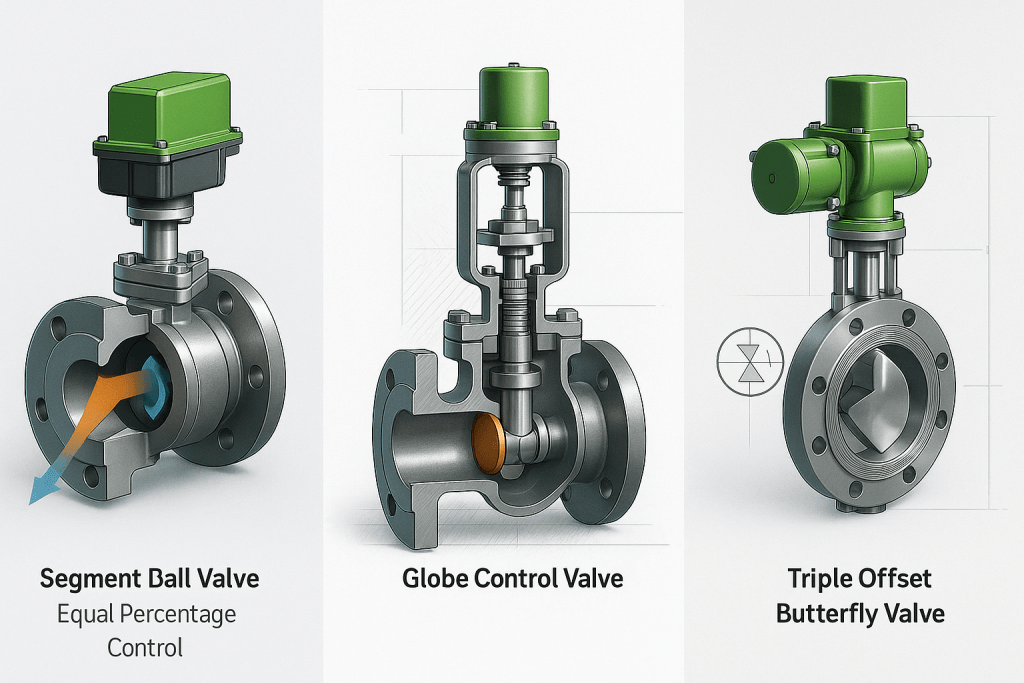

Also, we supply and integrate segment ball valves, globe control valves, and triple-offset butterfly valves, engineered for throttling, modulating, and on/off service, optimized for process reliability and safety integrity.

Our solutions are widely used in LNG, oil & gas, pulp & paper, power generation, marine, and chemical industries, ensuring consistent performance under harsh operating conditions.

Segment Ball Valves

Globe Control Valves

Triple Offset Butterfly Valves

Consultative:

Proper valve sizing is critical to avoid cavitation, flashing, and choked flow. Our technical team uses advanced sizing software to calculate the optimal Cv and noise levels for your specific P1 and P2 conditions.

Contact us for a detailed cavitation analysis and valve signature report.