Partial Stroke Testing (PST) and Smart Valve Positioners

NordenFlow delivers high-reliability Partial Stroke Testing (PST) solutions and advanced valve positioners engineered for safety-critical valve automation. These systems provide precise diagnostics for ESD valves, maintain SIL2/SIL3 compliance, and ensure dependable operation under demanding industrial conditions.

Our PST and positioner technologies are integrated into actuator assemblies, control panels, or complete skid packages to support continuous safety assurance and process accuracy.

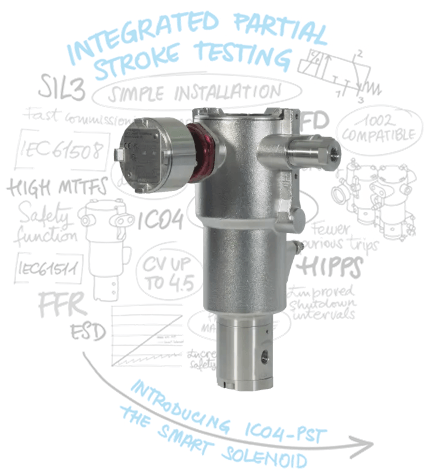

Partial Stroke Test (PST) Overview

PST systems verify the operational readiness of Emergency Shutdown (ESD) valves without interrupting production. They provide controlled partial movement of the valve (typically 10–20% of stroke), enabling verification of torque, movement, and mechanical integrity — essential for functional safety and minimizing unplanned downtime. Our systems identify up to 70% of potential dangerous failure modes, such as valve stiction, stem shear, or actuator seal failure, without disrupting production.

NordenFlow integrates both technologies into actuator assemblies or control panels for complete automation and safety assurance.

Partial Stroke Testing (PST) Modules

- Periodic proof testing of ESD valves without full closure

- Adjustable stroke range (5–25%) for flexible configuration

- Test initiation: local push-button or remote signal

- Automatic reset after test completion

- Continuous position feedback (4–20 mA or digital)

- Compatible with pneumatic, hydraulic, and electro-hydraulic actuators

- SIL2/SIL3 certified electronics

- Local visual indication and LED status

- Manual override and fail-safe protection

Smart Valve Positioners

NordenFlow positioners provide precise valve control for modulating service. They ensure stable, accurate valve response in harsh operating conditions, supporting both control valves and automated on/off valves.

Positioner Features

- Signal input: 4–20 mA, HART, Profibus, Modbus

- Output signal: pneumatic 0.2–1.0 bar

- Types: analog, digital, electro-pneumatic, or smart positioner

- Feedback options: potentiometer or encoder

- Housing materials: aluminum or SS316 (IP66 / Ex d / Ex ia)

- Mounting: Namur or IEC 60534 standard brackets

- Auto-calibration and self-diagnostics

- Optional local LCD for configuration and status monitoring

Integrated Safety & Control Solutions

NordenFlow combines PST systems and smart positioners into engineered automation packages for:

- Refinery ESD valve assemblies

- Power plant safety loops

- Oil & gas processing lines

- Chemical shutdown and control valve systems

- Industrial modulating control services

Our solutions deliver high integrity, accurate diagnostics, and compliance with global safety standards, ensuring dependable valve performance across the entire automation lifecycle

NordenFlow is the authorized distributor and technical partner for IMI Industrial Automation and Instrumentation solutions.