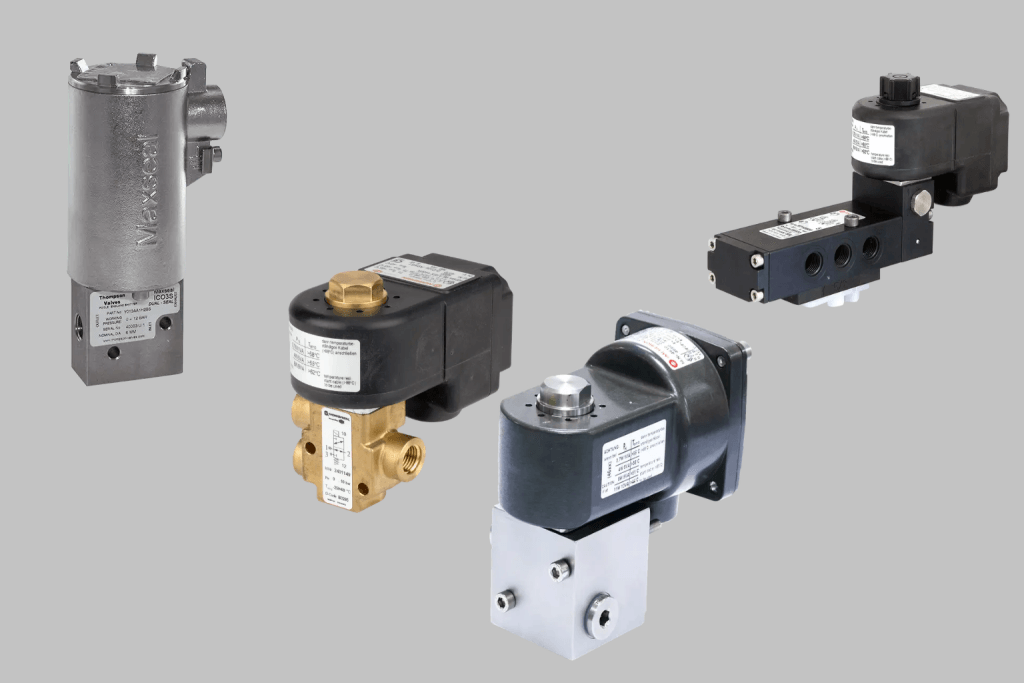

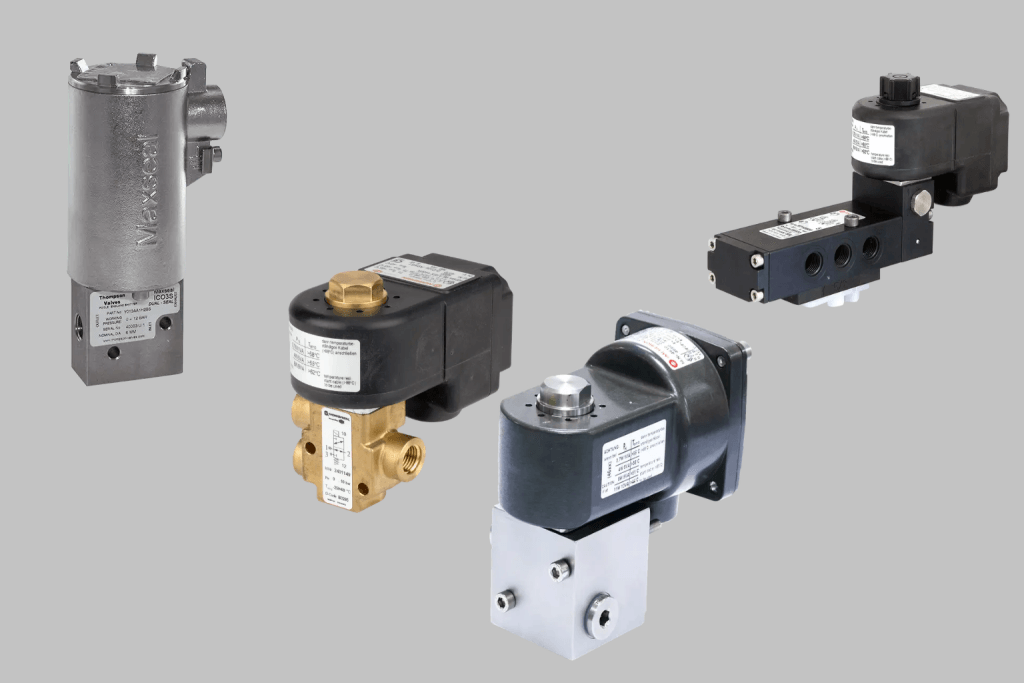

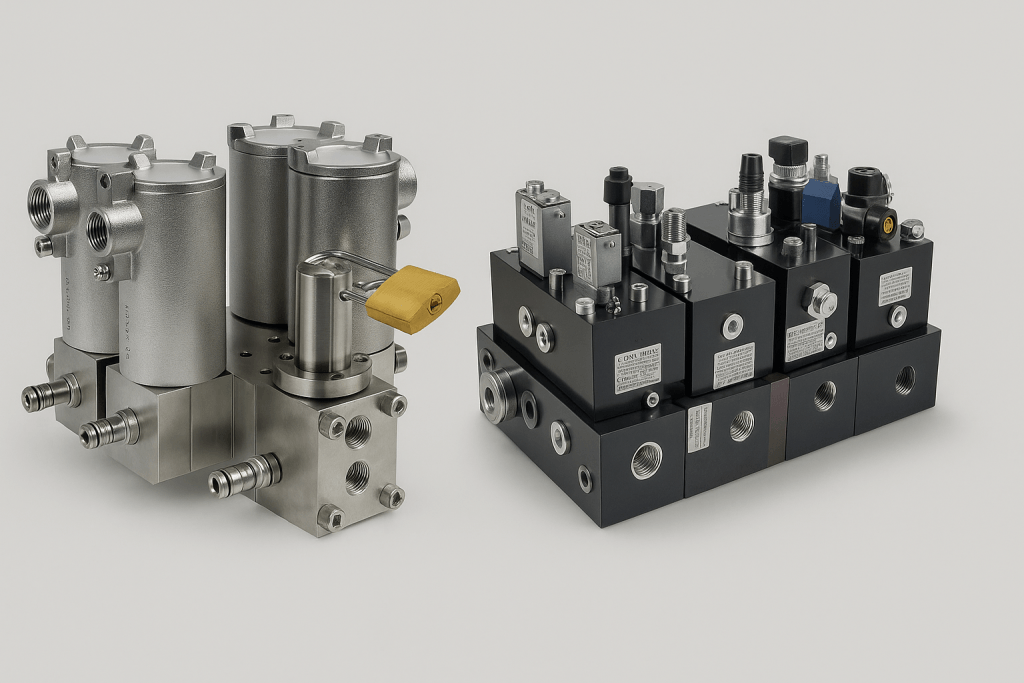

Solenoid Valves & Manifold Assemblies

NordenFlow delivers high-reliability solenoid valves and engineered manifold assemblies for demanding pneumatic, hydraulic, and gas-over-oil actuator systems.

Our range is optimized for high-flow capacity (Cv/Kv values) and low-power consumption, ensuring reliable fail-safe operation in Safety Instrumented Systems (SIS).

Designed for SIL2/SIL3 safety loops, ATEX environments, and mission-critical ESD applications, our solenoids deliver fast, accurate, and fail-safe control for the energy and industrial automation sectors.

⚙️ Product Overview

Solenoid valves are the primary control interface in Industrial automation packages, converting electrical commands into precise pneumatic or hydraulic actions.

NordenFlow solutions ensure stable performance, reduced downtime, and high integrity under severe operating conditions.

Product Range / Technical specification;

- configurations: 2/2, 3/2, 5/2, and 5/3 way

- Direct-acting and pilot-operated designs

- Electrical Specs: Wide range of coil voltages (AC/DC) with Class H insulation and manual override (MO) as standard.

12, 24 & 50 VDC, 110/230 VAC - Orifice sizes: 1.2 – 6.0 mm (customized on request)

- Flow capacity: up to 2000 l/min

- Mounting: Namur (VDE/VDI 3845), manifold, or panel type

- Materials: Hard-anodized aluminum, brass, or 316L Stainless Steel bodies for superior performance in corrosive offshore and chemical environments.

- Certifications: SIL 3 capable (IEC 61508), ATEX/IECEx explosion-proof, and IP65-IP67 ingress protection.

Moreover, the system meets SIL/ATEX requirements, ensuring compliance in demanding industrial and safety applications.

🔩 Technical Highlights

| Feature | Specification / Option |

|---|---|

| Standards | IEC 61508 / SIL2 / ATEX / CE / RoHS |

| Operation | On/Off, ESD |

| Ports | 1/8″ – 1 1/2″ BSP / NPT |

| Temperature Range | −40°C … +80°C (optional −60°C) |

| Mounting Interface | Namur or base manifold |

| Coil Protection | Encapsulated / Explosion-proof |

| Manual Override | Standard on most models |

| Options | Dual coil, redundant manifold, quick exhaust |

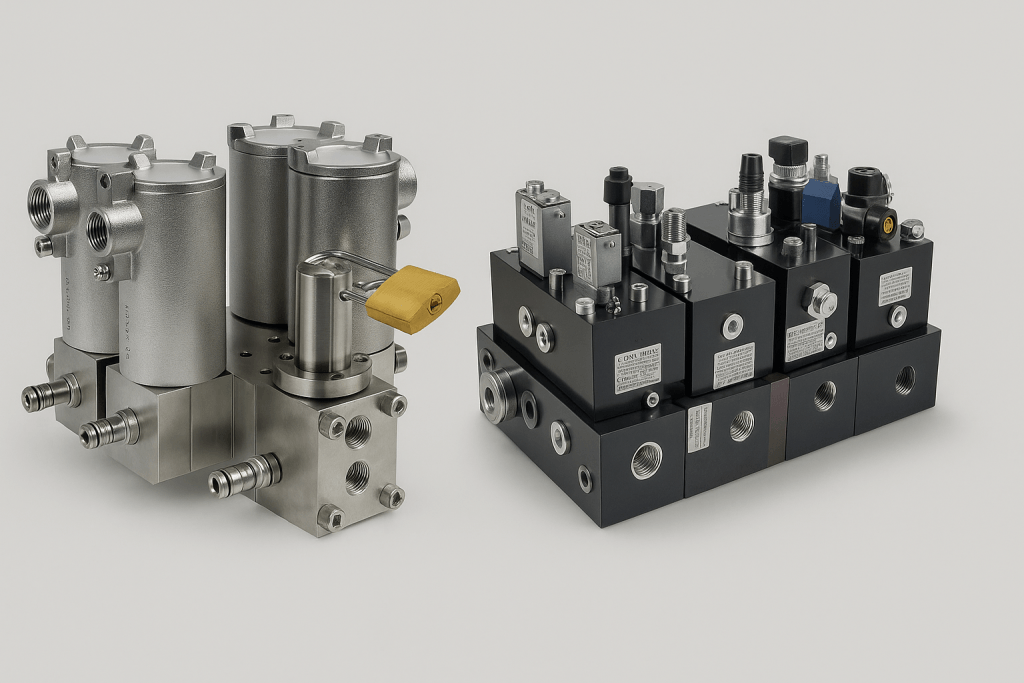

Manifold & Redundant Assemblies;

For high-integrity ESD systems, NordenFlow designs and assembles solenoid valve manifolds with redundancy, isolation, and diagnostic capabilities.

Each manifold is engineered for simultaneous, reliable operation of single or multiple actuators.In addition, the manifold design reduces installation time and simplifies maintenance.

Manifold Features:

- Modular 2–10 station aluminum or SS316 manifold blocks

- Integrated pressure gauges and isolation valves

- Quick exhaust and check valves built in

- SIL3-certified redundant solenoid configurations (1oo2, 2oo3)

- Supply Medium: Pneumatic / Hydraulic

- Factory-assembled and tested according to ISO 4414 / IEC 61511

- ATEX / SIL-certified for ESD & process safety

- Modular design simplifies installation and maintenance

- Compatible with PST and smart diagnostic systems

- Available as stand-alone units or fully assembled panels

Typical Applications

- ESD valve and blowdown control

- On/Off automation packages

- Pneumatic & Hydraulic actuator manifolds (Namur or remote)

- PST-enabled control cabinets

- Marine and LNG valve automation skids

Proportional Control (Norgren Series):

As an authorized Norgren distributor in Finland, NordenFlow provides advanced proportional pressure and flow control solutions. Unlike standard binary solenoid valves, our Norgren proportional range (including VP50, VP51, and VP10 series) offers precise, steeples regulation of compressed air and neutral gases through integrated closed-loop electronics.

NordenFlow is the authorized distributor and technical partner for IMI Industrial Automation and Instrumentation solutions.