Pneumatic Actuators for Reliable Valve Automation

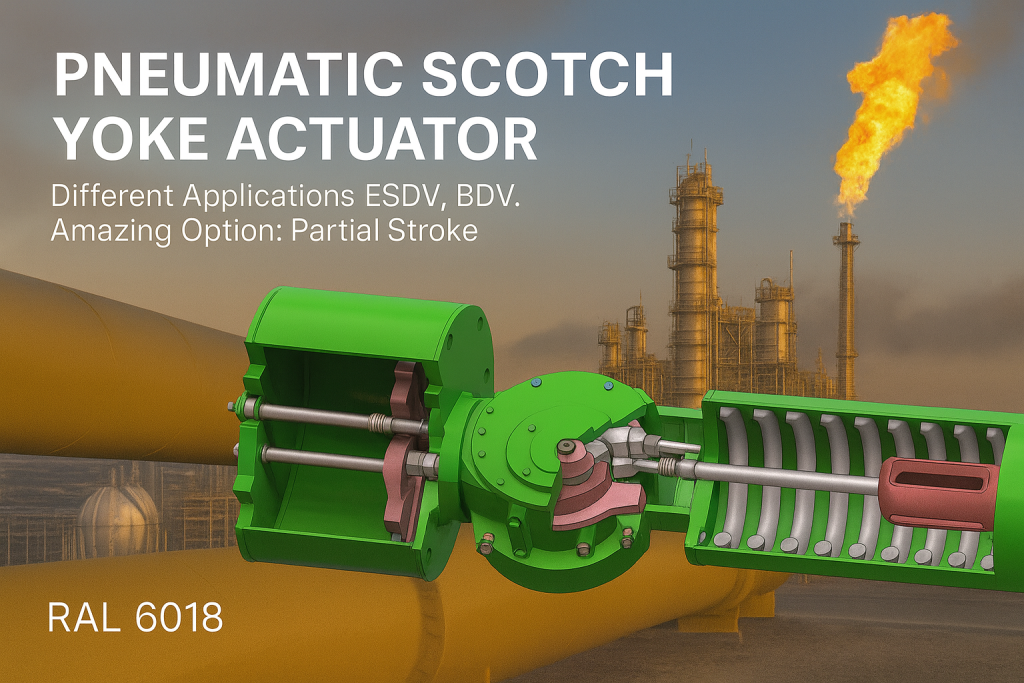

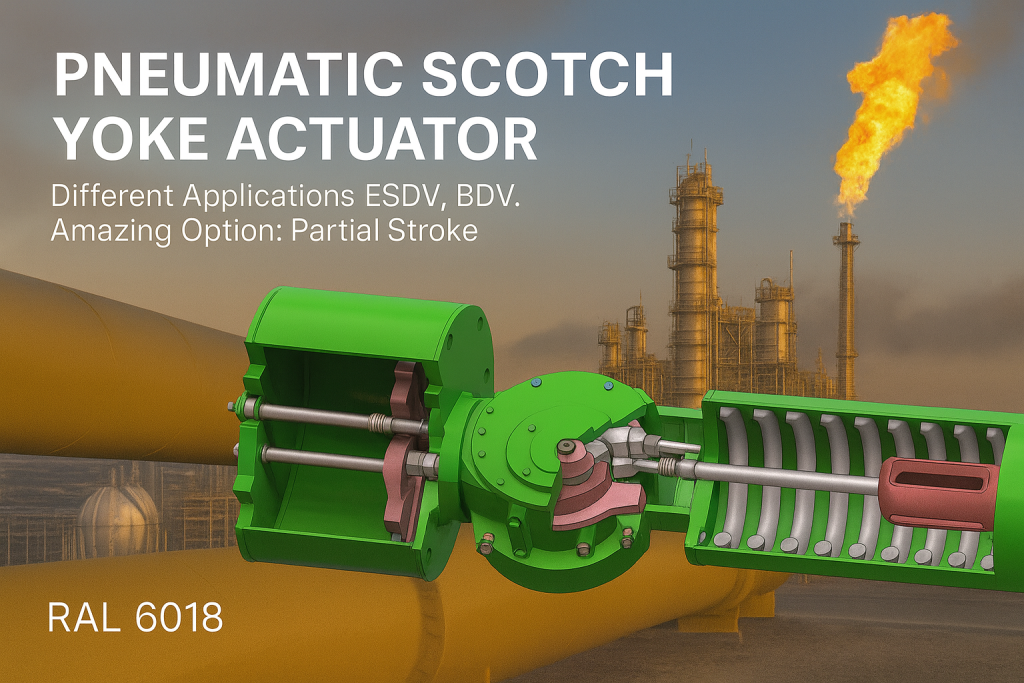

NordenFlow’s Pneumatic Part-turn Actuators are engineered for high-cycle reliability and precise valve control in critical industrial applications. Fully compliant with the EN 15714-3 standard, our actuators are available in various configurations, including rack & pinion and heavy-duty scotch yoke designs.

Designed to operate in extreme environments, these units are ATEX certified and SIL 3 capable, making them the ideal choice for Emergency Shutdown (ESD) and modulating control. We provide seamless integration with smart positioners and solenoid manifolds for complete automation packages in the Energy, Marine, and Pulp & Paper sectors.

Part-Turn (Quarter-Turn) Actuator

Rack & pinion or Scotch-yoke

High performance and high reliability

Fully compliant with the latest international regulations

More applicable specifications and higher cost performance

Better industrial shape is more suitable for various application environments

⚙️Technical Features

- Torque range: Up to 250,000 Nm (Scotch-Yoke) /

10,000 Nm (Rack & Pinion) - Designs: Double-acting / Spring-return

- Rotation: 90° (adjustable ±5°)

- Supply pressure: 2 … 8 bar

- Materials: Anodized aluminium / Carbon Steel /Stainless steel 316 housings

- Interfaces: Direct-mount for Solenoids and PST-Positioners

- Temperature: −40°C … +80°C (low-/high-temp kits)

- Protection: up to IP66/67

- Safety: SIL 3 Capable (IEC 61508), ATEX II 2 GD c T6

🔩 Key Advantages

- Compact footprint, high torque density

- Simple maintenance, interchangeable modules

- Excellent corrosion resistance (offshore/marine kits)

- Compatible with PST (Partial Stroke Test) for ESD verification

Typical Applications

- On/Off & control of ball/ butterfly/ plug valves

- ESD and Blowdown services (with PST)

- LNG, marine, pulp & paper, petrochemical utilities

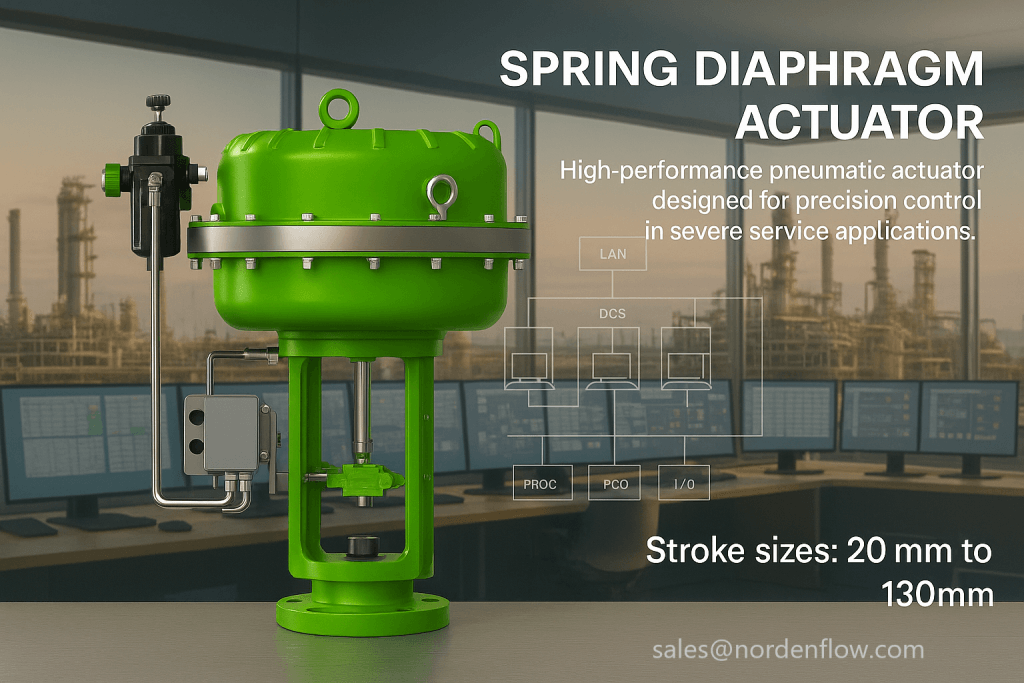

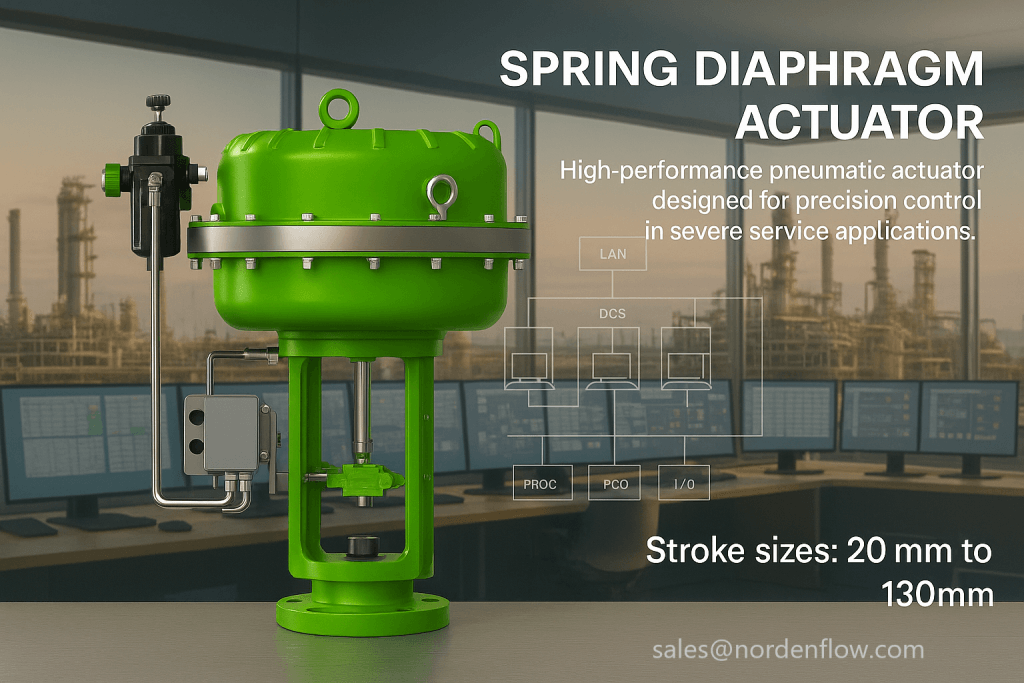

Linear Actuator

Diaphragm or Piston type actuator

Diaphragm Actuator is a high-performance pneumatic actuator designed for precision control in severe service applications

⚙️Technical Features

- Thrust force: 10 … 300 Kn (expand if needed)

- Designs: direct-acting (DA) and reverse-acting (RA) configurations

- Stroke sizes: 20mm to 130mm

- Cylinder standards: ISO 15552 / ISO 6431 (where applicable)

- Supply pressure: 4 … 8 bar

- Materials: Carbon Steel

- Position control: I/P + smart positioners, 4–20 mA/HART options

- Temperature: −40°C … +80°C (low-/high-temp kits)

- Protection: IP66/67; wiper/seal kits for dusty or corrosive media

- Top or side-handwheel manual override option

- Safety: SIL2-capable, ATEX/IECEx options for hazardous areas

🔩 Key Advantages

- High thrust with precise positioning

- Stable modulating control with low hysteresis

- Service kits and stem nut options for major valve brands

Typical Applications

- Globe/gate control valves (pressure/flow/level)

- Anti-surge & bypass control, steam conditioning

- Refinery, Petrochemical, Power plant, and water treatment loops

To ensure reliable field performance, we supply complete pneumatic valve packages integrating certified components like PST, regulators, solenoid valves (SOV), and Namur interface manifolds.

Packages & Accessories

- Solenoid valves (SS316 / Ex-proof), manifolds, quick-exhaust

- Filter regulators & high-pressure regulators

- Limit switches, smart & analog positioners

- PST modules and SOV test ports

- Mounting kits, ISO 5211 adapters, drive bushings

- Fire-proof jackets (optional)