Instrumentation & Control Solutions for Industrial Automation

Precision, safety, and reliability for pneumatic, hydraulic, and electro-hydraulic actuation systems.

Engineered for ESD, PSD, on/off, and modulating valve applications.

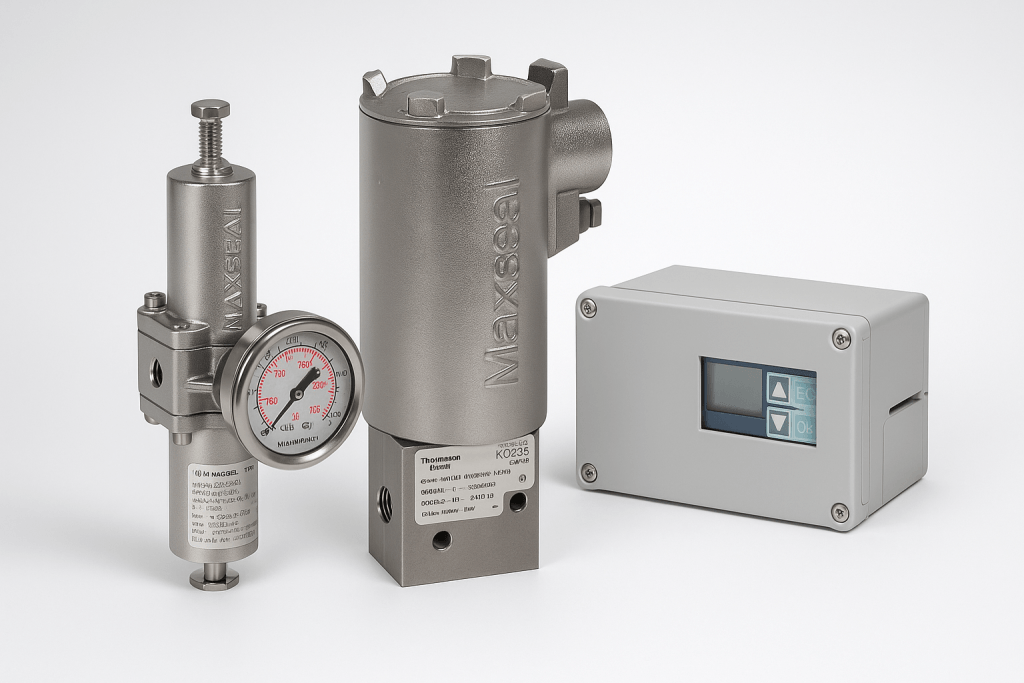

Complete Instrumentation Packages for Reliable Valve Automation

Nordenflow delivers fully engineered instrumentation and control solutions that ensure stable operation, fast response, and long-term reliability of your valve automation systems.

From solenoid valves and filter regulators to smart positioners and partial stroke testing (PST) modules, every component is selected and configured to guarantee safety performance, compliance, and lifecycle efficiency.

We specialize in high-integrity instrumentation and control solutions that bridge the gap between process logic and final element performance. Our integrated packages are engineered to enhance the safety, reliability, and diagnostic capabilities of automated valve assemblies in critical environments.

Our solutions are designed for industries operating in demanding conditions—LNG, marine, energy, petrochemical, refining, pulp & paper, and general process automation.

All instrumentation packages can be supplied ATEX, SIL2/3, or PED compliant and integrated directly into actuator assemblies or control panels.

Instrumentation Categories

Solenoid Valves & Manifolds

Filter & Pressure Regulators

Partial Stroke Test & Positioners

Instrumentation Technologies:

Digital Positioners:

High-resolution modulating control with HART, Foundation Fieldbus, and Profibus integration for real-time valve diagnostics.

Solenoid Control Systems:

High-flow, low-power solenoid valves and custom 316L stainless steel manifolds for reliable fail-safe operation.

PST (Partial Stroke Testing):

Intelligent testing solutions that verify valve availability without process interruption, significantly improving SIL (Safety Integrity Level) performance.

Limit Switches & Feedback:

Robust position monitoring with gold-plated contacts or inductive sensors for explosive atmospheres (ATEX/IECEx).

Typical Functions Across Industrial Processes

- On/Off and modulating valve control

- Emergency shutdown (ESD) and blowdown systems

- Air and gas filtration & regulation

- Feedback signaling and diagnostics

- Partial Stroke Testing (PST)

- SIL2/3-compliant safety loops

- Local and remote operation (control cabinets or skid units)

Integration & Engineering Support

Nordenflow integrates instrumentation directly into.

– Pneumatic, electric, and hydraulic actuator assemblies

– Control cabinets and automation panels

– Skid packages and custom solutions

Our engineering team ensures correct sizing, compatibility, wiring/piping layout, and documentation for fast installation, easy maintenance, and optimized plant performance.

Request a Complete Instrumentation Package

If your project requires a fully engineered control system—solenoid valves, regulators, manifolds, positioners, PST modules—our team will prepare a tailored solution with full compliance documentation.

Our team will prepare a tailored solution with full compliance documentation (Schematic, wiring and drawing), ensuring seamless integration and communication with your chosen pneumatic or hydraulic actuator.

NordenFlow is the authorized distributor and technical partner for IMI Industrial Automation and Instrumentation solutions.